- HOME >

- Our Business >

- Business plant Factory >

- Cultivation

Light source ■

"In-store Production/Consumption" System

We bring you vegetables with "safety and security"

The keyword is "In-store Production/Consumption"

A gardening system selected by a designer to match any stylish store interior.

A room with a display of fresh greens provides tranquility and relaxation.

An ultimate ECO model, with sound food mileage.

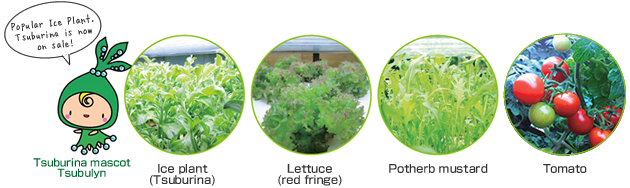

Vegetable types can be selected.

A compact seedling/ vegetable cultivation system

(air-conditioned environment control unit)

Compatible with both hydroponic and soil cultivation!

Seedling can also be provided on request.

| External size (width x depth x height) |

Approx. 1,300×850×2,450 (mm) |

|---|---|

| Culture shelf | 3-shelf system |

| HEFL lighting unit | 900×700×57(mm) with 12lamps |

| Cooling capacity | 20℃~25℃ |

| Power | 100V |

| Automatic temperature adjustment feature |

Available |

| Wattage range | Approx. 538-745W (with dimming control) |

* Specification may be changed without a preliminary announcement.

Rental Farm

New business model・・・

Effective utilization of underground shopping complexes in large cities・・・

Creates a comforting environment・・・

- Enjoy the experience of cultivating vegetables right up to harvesting them while also ensuring the safety of the vegetables that you want to eat.

- Take on the challenge of meticulously producing vegetables the way you want for your health and beauty.

- Cultivating seedlings is surprisingly challenging. Make use of these facilities to cultivate seedlings for your kitchen garden.

- Remote monitoring is possible. Check the condition of your seedlings daily using web cameras.

- Use this system as a "favorite cafe" that deliciously cooks your own vegetables.

- Delicious salad bars create places for people to relax with friends and family.

HEFL Plant Cultivation System [Container Type]

An example of mass production unit

- ◆Modular units to accommodate your needs.

- ◆Adaptable as a large scale seed incubator.

- ◆Possible for a streamlined cultivation from sowing to harvest within container spaces.

- ◆Insulated containers allow farming regardless of location.

Crop yields can be increased with the proximity lighting

taking advantage of the strengths of the HEFL.

Making use of our cultivation know-how,

this system can be installed in vacant lots, farms,

and warehouses and can stably produce crops throughout the year.

- ◆Air conditioning is easy in the heat-insulated container.

- ◆Workability is improved with the installation of water supply and drainage facilities to the system.

- ◆The process of sowing, seedling development, and harvesting is developed in a systematic manner based on our original cultivation know-how.

- ◆HEFL light level, temperature, humidity, pH, EC, CO2 level, etc. can be remotely monitored.(Optional)

【Specifications of a six-shelf system】

Outline of the system (In the case of a system in a 40-foot container)

| Cultivation shelves | 6-shelf system(L9,500xW730xH2,450mm) |

|---|---|

| HEFL lighting unit | 85 W(L900 x W700 x H50mm) |

| Circulation tank | Capacity:around 1,000 liters |

| Circulaion pump | Two units attached |

| Air conditioner | Equivalent to 6 horsepower |

| CO2 supplying device | Optional |

| Room lamp | 40 W x 2 lamps |

| Total electric capacity | Total electric capacity Approx. 16 kw (Actual 12 kw) |

Example of the cultivation system in our company

(on the premises of the Nagahama Plant)

- ◆System with two interconnected containers

The preparation room and two cultivation rooms are integrated. - ◆Interconnection han increased the work efficiency and crop yield!

- ◆The system started operation at the end of June 2010.