- HOME >

- Technology >

- HEFL Lighting Unit

Technology

What is the HEFL?

We developed the Hybrid Electrode Fluorescent Lamp (HEFL) by improving the backlight used in large screen LCD TVs and are now developing plant growth lighting systems based on this lighting technology.

The features of this lighting technology are as follows:

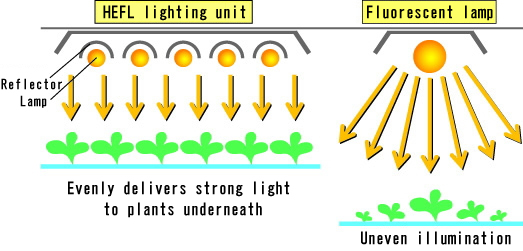

- The thinner lighting unit enables the number of shelves in a multi-shelf cultivation system to be increased.

(Up to 8 shelves can be set in a 2.7-meter system when a liquid fertilizer tank is installed at the bottom and the height of the plants is 22 cm at a maximum.) - With a specially designed reflector to direct light vertically downward, strong light, 200 to 250 PPF*, can be provided to plants with less energy. We have also produced a customized unit that provides 220-wat light of 450 PPF from light sources 30 cm away.

(In comparison with our conventional products, the unit gives 30% brighter light with 23% less energy.) - Light is distributed evenly to plants, and the positions of the proximal light sources are adjusted to the height of the plants as they grow in a multi-shelf cultivation system.

As the surface temperature of the lamps is relatively low, the system reduces waste heat and the cost of electricity for air conditioning. - The life of the tubes is as long as 40,000 hours, which leads to reduction of the maintenance cost for the lighting unit.

- Tubes are available in sizes ranging from 450 mm to 1,200 mm and can meet various demands for different levels of light quantity and designs.

- Different wavelengths necessary for plant growth (blue, red, white, ultraviolet, for infrared etc.) are available for a wide range of research activities.

HEFLs are replaceable. Please consult us about customized specifications and wavelengths.

- Ref :

- * PPF: Photosynthetic Photon Flux

In general, leaf vegetables and fruits need 150 and 300 PPF of light for growth, respectively.

Technology

HEFL lighting unit line-up

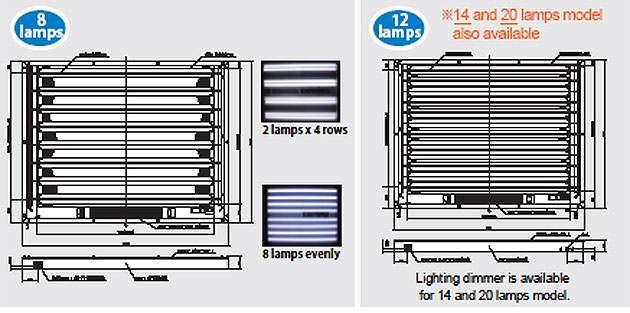

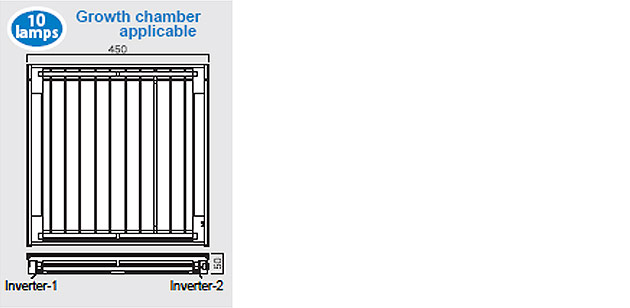

| Basic model | Growth chamber | ||||

|---|---|---|---|---|---|

| 8lamps | 12lamps | 14lamps | 20lamps | 10lamps | |

| Size | 700mm×900mm T:57mm | 750mm×900mm T:57mm | 450mm×450mm T:50mm | ||

| Lamp spec. | 852mm φ3.4/4mn | 420mm φ3.4/4mn | |||

| Power consumption | 70~90W | 110~115W | 120~160W | 175~225W | 60W |

| Voltage | 100~240V | 100V(W)(AC adpt) | |||

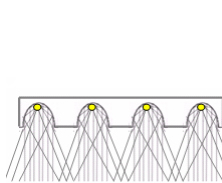

- Standard equipment・・・Parabolic-shaped reflector to deliver light vertically downward

- Light weight・・・8lamps:7kg 12lamps:8kg

- Option・・・Dimmer(Adjustable 30-100%)

- Tubes can be replaced

Characteristics of the wavelengths of the HEFL

In the cultivation of plants, it is believed that the blue wavelength helps leaves and stalks grow in a normal shape and that the red wavelength promotes photosynthesis.

The HEFL offers a range of wavelengths necessary for cultivation of plants.

HEFL tube colors: 17 colors in total

| ●White | |||

6000K |

30000K |

||

| ●Red | ●Blue | ||

610nm |

450nm |

||

| ●Green | ●Ultraviolet | ||

550nm |

UV-A |

||

| ●Far-infrared | |||

Three wavelength + 740nm |

740nm |

||

| ●Mixed color | |||

| ← Closer to blue (1) (2) (3) (4) (5) Closer to red → | |||

| (1)Very close to blue |  (1)Very close to blue (1)Very close to blue |

(3)Half way between blue and red |

(4)Close to red |

| (2)Close to blue | |||

| (3)Half way between blue and red | |||

| (4)Close to red | |||

| (5)Very close to red | |||

(2)Close to blue |

(5)Very close to red |

||

* Please contact us about special orders.

Wavelength experiment

The table below shows the results of an experiment to cultivate two kinds of vegetables by irradiating them with the red (610 nm) and blue (450 nm) wavelengths until they grew from seeds into mother plants.

| Red wavelength (610 nm) | Blue wavelength (450 nm) | |

| Stalks | Break easily | Long and strong |

| Weight | Heavier (approx. 1.3 times heavier than with the blue wavelength) | Lighter than with the red wavelength |

| Pigment | No residual pigment | Tend to have residual pigment |

| Shape | Larger leaves | Good leaf shape |

|

|

The growth of vegetables depends on the use of red or blue wavelength.

Blue wavelength also increases the vitamins and polyphenol in some species of vegetables.

Vegetable cultivation system using HEFL lighting units

1.High productivity

Taking advantage of the low heat emission of the HEFL, this system can provide light to vegetables from proximal light sources and increase the number of shelves to expand the yield of a cultivating chamber.

The system adjusts the height of the light sources as the plants grow.

2.Efficient and energy-saving HEFL lighting system delivering light vertically downward

With specially designed reflectors, this system can deliver strong light (200 to 250 PPF) to the plants under the lamps.

The lamps emit less heat, which is helpful for plant growth.

|

|

▲HEFL light is delivered vertically downward with specially designed reflectors (cultivation of frill lettuce). |

▲Specially designed reflector

|

|

3.Cultivation without using agrichemicals

Plants are cultivated in a hygienic room isolated from the outside world. The soil-free hydroponic system requires no agrichemicals. There is, therefore, no potential for soil pollution or contamination with external agrichemicals.

4.Scheduled production for stable supply

Cultivation of plants in a hygienic room realizes stable production and is unaffected by external factors such as weather conditions. It is also possible to improve the nutrition of vegetables through management of the cultivation environment and application of liquid fertilizers.

▲Artificial cultivation of strawberries

5.Cultivation of strawberries and seedlings is also possible

Cultivation of strawberries and tomato seedlings is believed to require around 300 PPF of light. The HEFL lighting system can cultivate strawberries and tomato seedlings for stable supply all year round.